2703/500 Elizabeth St,

Melbourne VIC 3000,

Australia.

EXCELUBE supplies environmental-friendly process oils to tyre and rubber products manufacturing companies. The process oils are made from crude petroleum and used widely in rubber compounds for manufacturing of rubber components in cars, appliances such as tyres, footwear, foams, belts, seals, hoses, wires, rubber mat, waterproof materials, etc. The rubber process oils are high boiling petroleum fractions obtained in refining after gasoline, fuel oil, and other low boiling compounds are removed by distillation. The process oils have high viscosity, low volatility and high solvency for the rubber compounds. Process oils in rubber compounds serve three main purposes:

Due to health and environmental concerns, green rubber process oils – Green RPO (non-carcinogenic oils) are gaining importance for use in tyre compounds. We supply two types of Green RPO, namely Residual Aromatic Extract (RAE) and Treated Distillate Aromatic Extract (TDAE). For certain products which are not in close contact during application and do not require Green RPO specification, the normal Aromatic Rubber Process Oil proved to be a cost-effective option. Read more in our product section for the following product specifications:

Contact us at enquiry@excelube.com for more information. | ||

Treated Distillate Aromatics Extract (TDAE) |  Aromatic Rubber Process Oil (ARPO) |  Residual Aromatic Extract (RAE) |

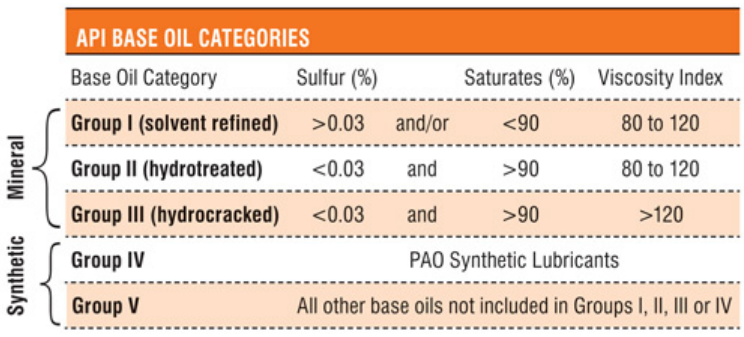

EXCELUBE supplies quality base oils to Lubricant and petroleum products manufacturing companies. Base oil is a core component for automotive and industrial lubricants. Automobile, engines and machineries are the world’s biggest consumers of lubricants. With industry sectors pushing endlessly to meet stiffening efficiency and pollution standards, they drive the way base oils are produced. For Australia market, we supply Group I Base Oils, Group II Base Oils and Group III Base Oils from regional refineries with reasonable price-advantage even during market uncertainty and supply scarcity.General properties of base oils as per table below*:  * As per American Petroleum Institute (API 1509) categories Read more in our product section for our range of base oil product specifications:

Contact us at enquiry@excelube.com for more information. | ||

GROUP III BASE OIL 3 cSt |  GROUP II BASE OIL 70N |  GROUP III BASE OIL 4 cSt |

Over the years of operation, we go the extra miles and provide additional services to ensure top product quality. Complementary product testing using international recognised certification standard by our associate testing providers are provided for every production batch. EXCELUBE also provides OEM services for production of Automotive and Industrial Lubricants at competitive prices due to our cost-effective manufacturing location. This is achieved through a winning combination of state-of-the-art manufacturing capabilities with our technical partners, market knowledge and petroleum products’ price-advantage. We can produce customised product to meet customer requirement for automotive and industrial lubricants.Contact us at enquiry@excelube.com for more information. | ||

OEM Services |  Independent Petroleum Oil Testing Services | |